How a CREATE-X Startup at the Biltmore Is Empowering Innovators

In the startup or innovation space, things move lightning fast. In fact, waiting just a week for the next iteration of your customized circuit board to be printed could be a significant setback. “Startups move fast, and innovators need their circuit boards as quickly as possible. Waiting weeks for a specialized board isn’t an option. Convexity Electronics’ goal is to be more local and convenient,” shares Calla Scotch, Founder and Lead Technical Developer of Convexity Electronics.

“Startups move fast, and innovators need their circuit boards as quickly as possible. Waiting weeks for a specialized board isn’t an option. Convexity’s goal is to be more local and convenient.”

— Calla Scotch, Founder and Lead Technical Developer of Convexity Electronics

Convexity Electronics Team: Calla Scotch, Anuj Pandey, and Atharva Lele. Photo: Convexity Electronics

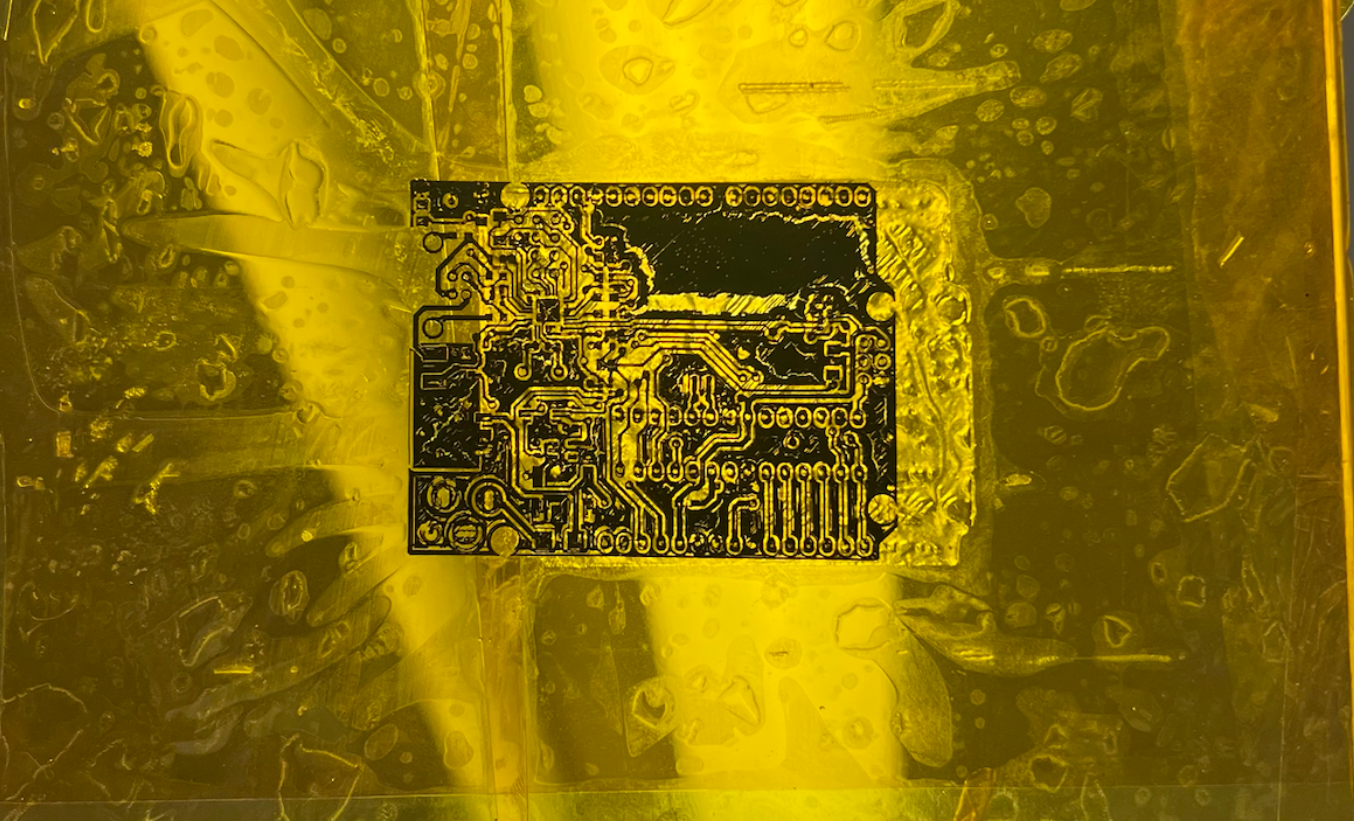

A Georgia Tech student-founded startup, Convexity Electronics, is helping innovators stay in their highly creative flow while staying on schedule and on budget by developing scalable 3D-printed circuitry based on local hubs to replace outdated printed circuit board (PCB) fabrication. This highly customizable process will allow designers and makers to expand their design and innovation possibilities of PCBs while also reducing wait times, cutting down on supply chains, and shortening the distance to producers.

The Convexity Electronics team, who started working together in December 2024, are all currently students at the Georgia Institute of Technology. The team builds 3D-printed circuitry from their expertise in various fields, including software development, 3D printing, coding, mechanics, and materials. Calla Scotch (School of Materials Science and Engineering, ’27), the Founder and Lead Technical Developer, brings a lifelong passion for robotics, coding, and building. Co-founder Anuj Pandey (Mechanical Engineering, ’26) and co-founder Atharva Lele (Chemical and Biomolecular Engineering, ’27) ensure precision in chemical manufacturing and mechanical processes.

Making 3D Printed Circuit Boards that are Local, Customizable, and Fast

Just as we can use building blocks, such as Legos, to construct structures piece by piece, additive manufactured electronics (AME) are created by adding layers of circuit board and copper specifically where they are needed. Convexity Electronics aims to manufacture PCBs at scale using additive 3D printing, meeting the expected and recognized quality standards for customers.

The benefits of this AME approach include enhanced design options, smaller circuitry, more complex electronic devices, more cost-effective, and faster lead times in comparison to traditional lithography-based methods, which are a subtractive method that removes materials from a starting piece of material, like how a sculptor creates a final work of art from an initial block of marble. These subtractive lithography-based techniques have been traditionally used in PCB fabrication, and materials are removed with a strong acid. In comparison to AME PCB fabrication, this traditional lithography-based method is expensive, slow, uses excess materials, and requires strong chemicals. Calla adds that, “subtractive PCB fabrication technology has not changed for the past 30 years as it’s currently optimized.”

In addition to the customization available to support innovators' creativity, resourcefulness, and iteration, Convexity Electronics will operate and manage localizable 3D-printing PCB hubs to bring manufacturing closer to makers in the United States. This will better meet demands and maintain consistency while also being more resistant to the impacts of tariffs and supply chain constraints. While circuit boards are found in many electronic devices, including computers, cars, and cellphones, most are still made outside the United States. “When boards are made locally, they can also be re-spun,” Calla adds.

Intriguing Makers, Innovators, and Attendees at CREATE-X Demo Day

Convexity Electronics’ solution resonated with participants at the CREATE-X Demo-Day, an event featuring 100-plus startups from Georgia Tech. Attendees’ enthusiasm was tangible regarding Convexity Electronics' progress and their 3D-printed PCB prototype.

Convexity Electronics' success has been charged by its connection with and support from researchers at the Georgia Institute of Technology, including Dr. Blair Brettman, an Associate Professor in the Georgia Institute of Technology’s School of Materials Science and Engineering. The Brettmann Research Group provides a laboratory space for Convexity Electronics to develop materials. Additionally, Convexity Electronics has another space on campus where they have access to oscilloscopes, waveform generators, and other prototyping equipment needed for their work.

This progress resulted from 12 weeks of hard work over the summer as part of the CREATE-X Startup Launch accelerator program, which included refining Convexity Electronics’ pitch. Demo-Day, held on August 20, 2025, featured over 100 Georgia Tech startups and had over 1,500 attendees in Georgia Tech’s Exhibition Hall.

The Challenge of Creating a Perfect Four-Layer PCB Every Time in Just One Hour

The Convexity Electronics team continues to work towards their new goals, following the 2025 CREATE-X 12-week accelerator program and Demo Day participation, placing second in the Fall 2024 CREATE-X Idea to Prototype (I2P) showcase, and being awarded the 2025 Inventure Prize of $20,000, which is the largest undergraduate student innovation competition in the United States. Related to placing first in the 2025 InVenture Prize Competition, the Convexity Electronics team shared that, “[this shows] the world that innovation does not require a billion-dollar budget or an army of engineers- it takes relentless curiosity, grit, and a willingness to challenge the status quo.”

To create perfect four-layer PCBs every time in just one hour, they are expanding their team, who will also be Georgia Tech students. Related to building a product that is competitive with traditional manufacturing, Calla shared that, “we want to be the first to meet standards of traditional methods.”

Convexity Electronics plans to collaborate with industrial engineers to develop the logistics of the distribution of manufacturing models, supply chains, and shipping methods. Additionally, collaborations will be developed related to both the development of the printer network software, which is new for PCB work, and environmental analysis to ensure this technology is safe for the world while remaining affordable.

Building Your Future: An Inspiring Message for Students

Calla has had a lifelong interest in building and was “desoldering materials and electronic boards from toys to develop something new” as a child. As a Fall 2025 teaching assistant for Georgia Tech’s evidence-based entrepreneurship course, CREATE-X Startup Lab, Calla is now sparking inspiration among students and shares, “If you are an undergraduate student wanting to make things, start now. Don’t wait until graduate school or beyond to start practicing these skills.”

CREATE-X Startup Lab teaches methods, including how to build for customers, get feedback, work iteratively, and identify gaps and needs. The Convexity Electronics team asks, how can you explore ways to build and test something yourself? Where are the resources, publications, and collaborators that you would seek and reach out to? Who can you talk with, listen to, and learn from, including potential customers, competitors, and those within the industry who understand the problem space?

Throughout each iteration, Convexity Electronics continues to provide a source of inspiration for us all to be curious, continual learners, and creative in our problem-solving. And of course, to have fun while we research, build, test, and iterate.